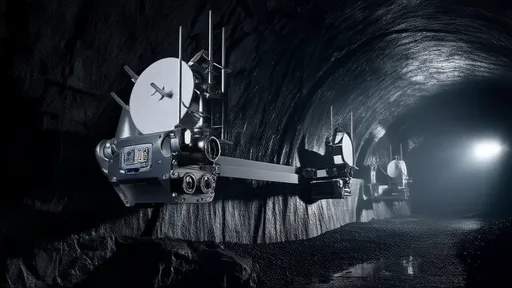

The mining industry has long grappled with the challenge of accurately tracking and positioning equipment deep underground. Traditional methods, such as RFID or ultrasonic sensors, often fall short in the harsh and complex environments of subterranean operations. However, the emergence of millimeter-wave (mmWave) radar technology is poised to revolutionize this space, offering unprecedented precision and reliability for underground asset localization.

Millimeter-wave radar, operating in the 30 to 300 GHz frequency range, brings several advantages to underground mining operations. Unlike optical or infrared systems, mmWave signals can penetrate dust, smoke, and low-light conditions—common obstacles in mining environments. This capability ensures consistent performance even in the most challenging scenarios where visibility is compromised. Furthermore, the shorter wavelength of mmWave allows for higher resolution in detecting and tracking objects, enabling centimeter-level accuracy in positioning.

The implementation of mmWave radar in underground equipment tracking addresses a critical need for real-time data. Mining operators can now monitor the exact location of heavy machinery, personnel carriers, and other mobile assets with minimal latency. This real-time visibility not only enhances operational efficiency but also significantly improves safety by preventing collisions and enabling rapid response in emergency situations. The technology’s ability to function without relying on external infrastructure, such as GPS, makes it particularly valuable in the depths of a mine where satellite signals are nonexistent.

One of the most compelling applications of mmWave radar in underground mining is autonomous or semi-autonomous vehicle navigation. As the industry moves toward automation, precise positioning becomes indispensable. MmWave radar systems can create detailed 3D maps of the mine’s interior, allowing autonomous loaders, drills, and haul trucks to navigate narrow tunnels and avoid obstacles with remarkable accuracy. This reduces the reliance on human operators in hazardous areas, mitigating risks and increasing productivity.

Another key benefit of mmWave radar is its resilience to interference. Underground mines are rife with electromagnetic noise from heavy machinery, power lines, and communication systems. Traditional wireless positioning technologies often struggle in such environments, but mmWave radar’s high-frequency signals are less susceptible to disruption. This reliability ensures uninterrupted operation, even in electrically noisy conditions, making it a robust solution for long-term deployment.

The integration of mmWave radar with existing mining systems is also straightforward. Many modern mining operations already employ IoT platforms and centralized control systems. MmWave radar data can be seamlessly fed into these platforms, providing operators with a unified view of all underground activities. This interoperability enhances decision-making and allows for more efficient resource allocation, ultimately driving down operational costs.

Despite its many advantages, the adoption of mmWave radar in mining is not without challenges. The initial cost of deploying high-frequency radar systems can be substantial, and mines must ensure that their personnel are trained to interpret and act on the data provided. Additionally, the technology’s performance can be affected by extreme environmental conditions, such as high humidity or temperature fluctuations, though ongoing advancements are steadily mitigating these limitations.

Looking ahead, the future of mmWave radar in underground mining appears promising. Researchers are exploring ways to enhance the technology’s range and resolution, while also reducing power consumption. As these improvements materialize, mmWave radar is likely to become a standard feature in smart mining operations worldwide. Its ability to deliver precise, real-time positioning in the most demanding environments positions it as a game-changer for the industry.

In conclusion, millimeter-wave radar represents a significant leap forward in underground equipment localization. By combining high accuracy, environmental resilience, and seamless integration with existing systems, it addresses longstanding pain points in mining operations. As the technology continues to evolve, its adoption will undoubtedly accelerate, paving the way for safer, more efficient, and more automated mining processes in the years to come.

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025

By /Aug 7, 2025